OEM Factory for Chopped Fiber Composites - Sandwich Panels Series – WANHOO

OEM Factory for Chopped Fiber Composites - Sandwich Panels Series – WANHOO Detail:

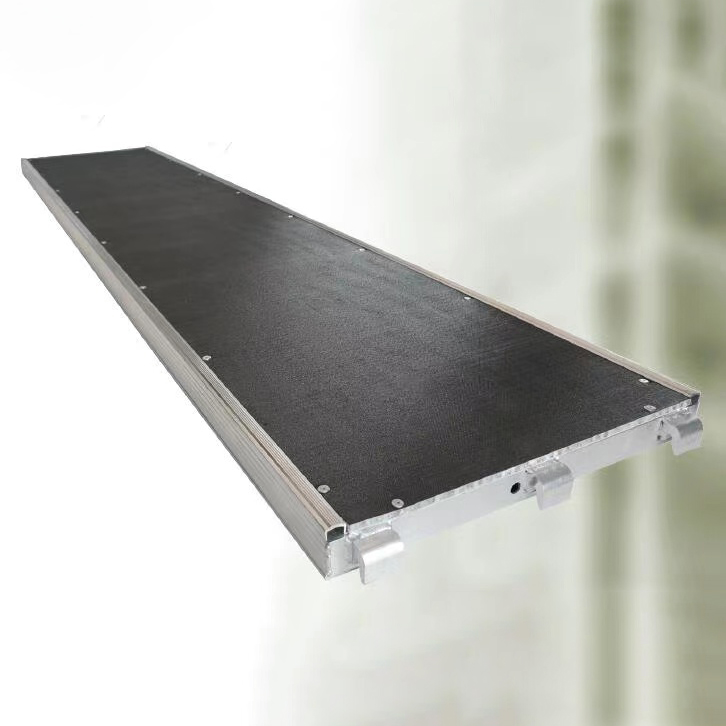

The Introduction of Honeycomb composite Scaffold board

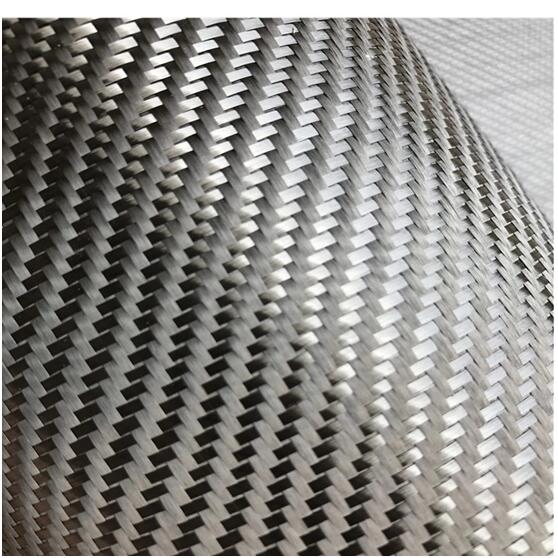

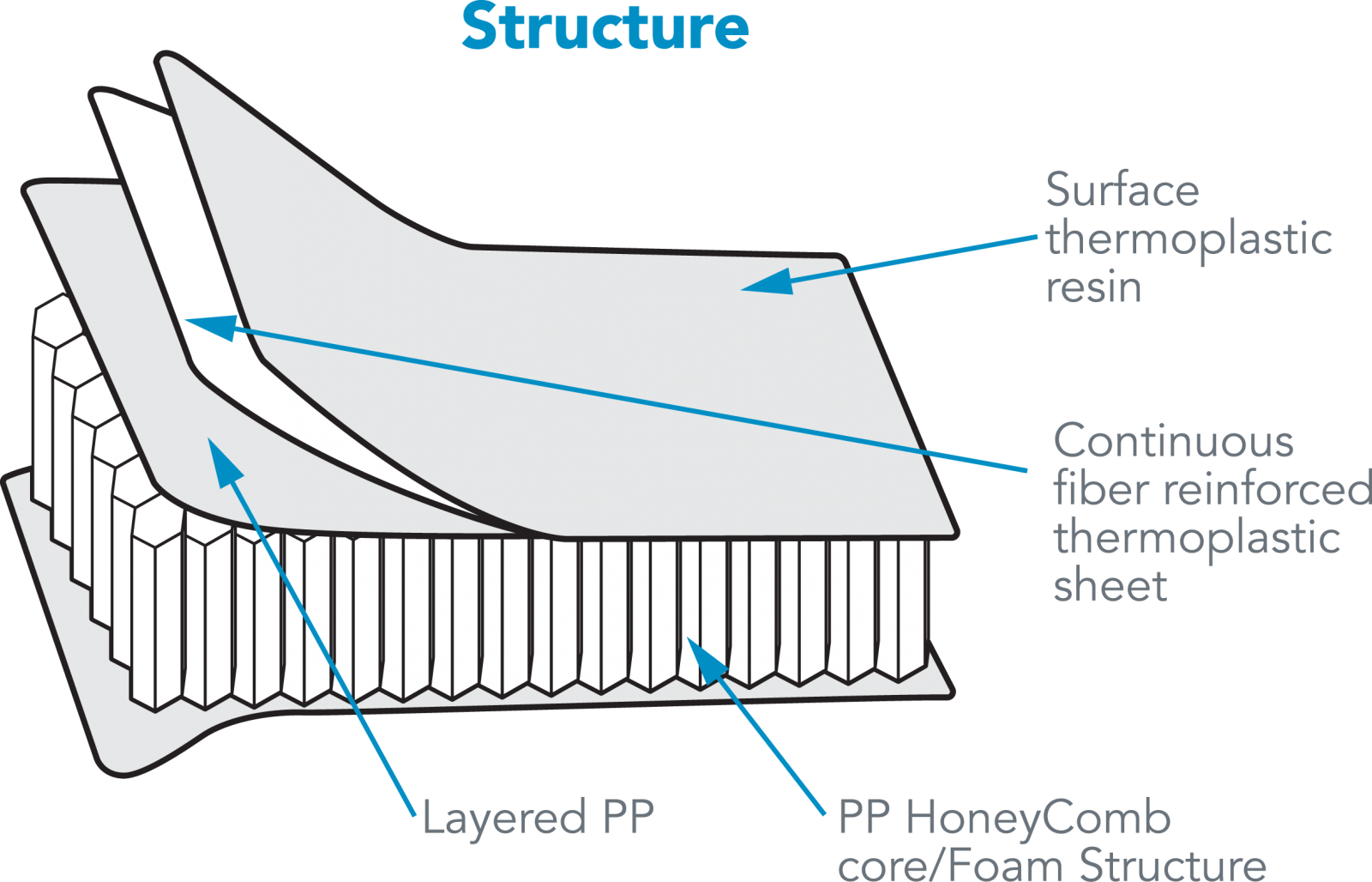

This Sandwich Panel product uses outer skin as the core, which made by continuous glass fiber (high strength, high rigidity and high toughness) mixed with thermoplastic resin. then composite with polypropylene (PP) honeycomb core through Continuous thermal lamination process.

why we use this structure

This involves high-end bionic design. In short, the bottom of each cell of the hexagonal honeycomb core is composed of three identical rhombies. These structures are “exactly the same” with the angles calculated by modern mathematicians.

And It is the most economical structure. The board made of this base is of high strength, light weight, high flatness, large capacity and extremely strong, and it is not easy to conduct sound and heat

Advantages

Light weight

Due to the special honeycomb structure, the honeycomb panel has very small volume density .

Taking 12mm honeycomb plate as an example, the weight can be designed as 4kg/ m2.

High strength

The outer skin has good strength, the core material has high impact resistance and overall stiffness, and can resist the impact and damage of large physical stress

Water-resistance and moisture-resistance

It has good sealing performance and we does not use glue during our production process

There is no need to worry about the impact of long-term outdoor use of rain and humidity, which is the unique difference between the material and wood board

High temperature resistance

The temperature range is large, and it can be used in most climatic conditions between – 40 ℃ and + 80 ℃

Environment protection

All the raw materials can be 100% recycled and have no impact on the environment

Parameter :

Width: it can be customized within 2700mm

Length: it can be customized

Thickness: between 8mm~50mm

Color: white or black

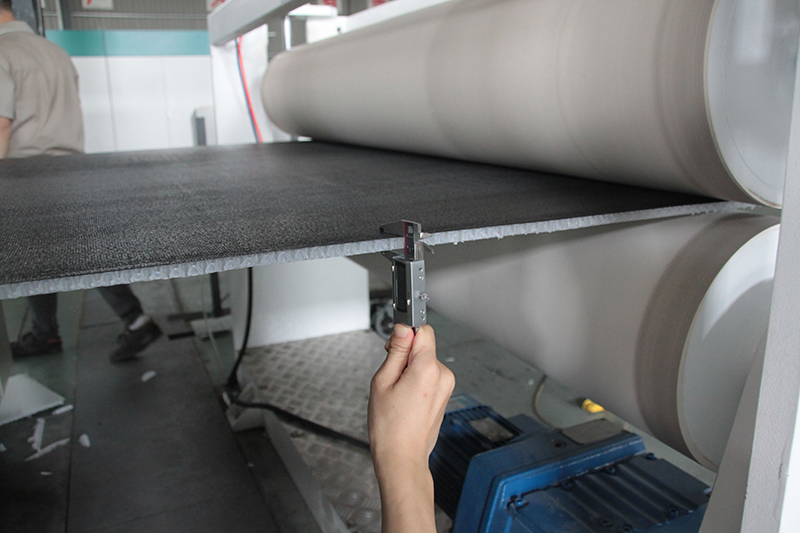

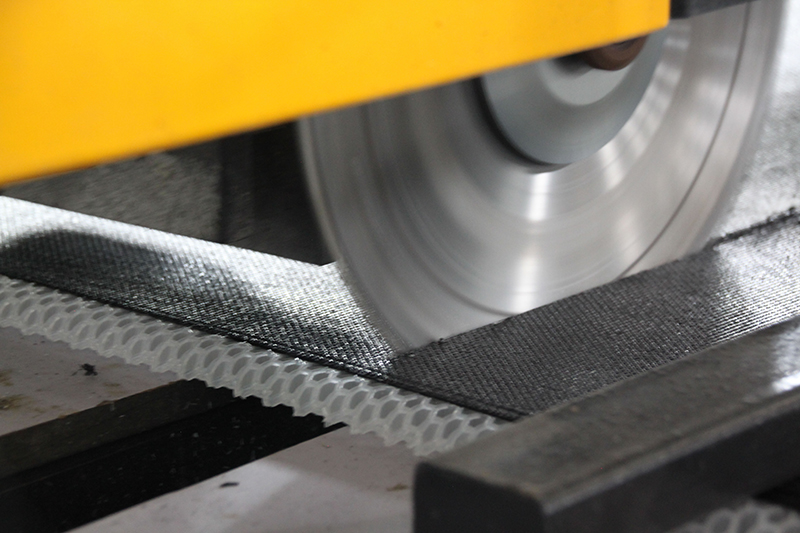

The foot board is black. The surface has pitting lines to achieve the effect of anti slip

Product detail pictures:

Related Product Guide:

Adhering to the principle of "quality, service, efficiency and growth", we have gained trusts and praises from domestic and international client for OEM Factory for Chopped Fiber Composites - Sandwich Panels Series – WANHOO , The product will supply to all over the world, such as: Canberra, Poland, luzern, We also provide OEM service that caters to your specific needs and requirements. With a strong team of experienced engineers in hose design and development, we value every opportunity to provide best products for our customers.

The product classification is very detailed that can be very accurate to meet our demand, a professional wholesaler.