OEM Factory for Chopped Fiber Composites - Reinforced Thermoplastic Pipe – WANHOO

OEM Factory for Chopped Fiber Composites - Reinforced Thermoplastic Pipe – WANHOO Detail:

Reinforced Thermoplastic Pipe

Reinforced thermoplastic pipe (RTP) is a generic term referring to a reliable high strength synthetic fibre (such as glass, aramid or carbon)

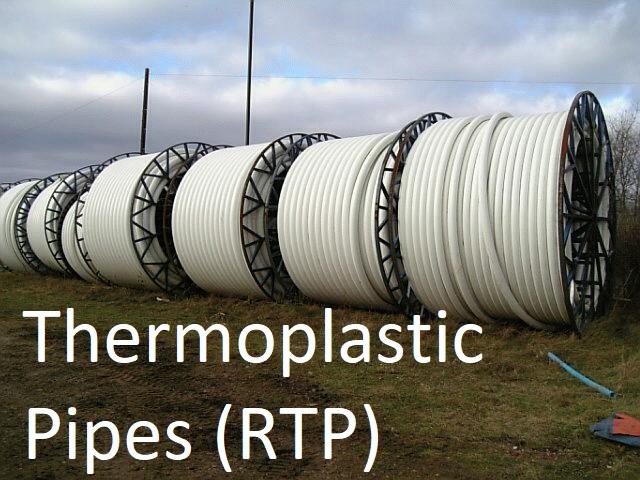

its main features are corrosion resistance/ high operation pressure endurance and keeping flexibility at the same time, it can be made into a reel form (continuous pipe), with a length from tens of meters to kilometers in one reel.

Over the last few years this type of pipe has been acknowledged as a standard alternative solution to steel for oilfield flowline applications by certain oil companies and operators. An advantage of this pipe is also its very fast installation time compared to steel pipe when considering the welding time as average speeds up to 1,000 m (3,281 ft)/day have been reached installing RTP in ground surface

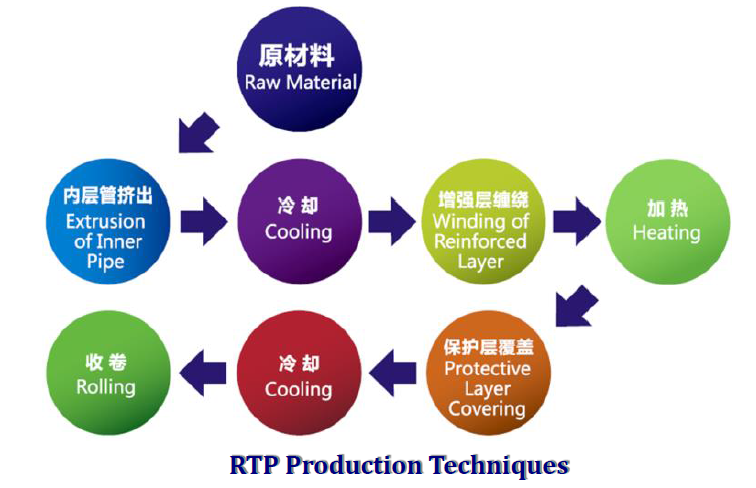

RTP production Techniques

The reinforced thermoplastic pipe consists of 3 basic layers: an internal thermoplastic liner, a continuous fiber reinforcement helically wrapped around the pipe, and an external thermoplastic jacket. The liner acts as a bladder, the fiber reinforcement provides strength, and the jacket protects the load-bearing fibers.

Advantages

High-pressure resistance: The maximum pressure resistance of the system is 50 MPa, 40 times of plastic pipes.

High-temperature resistance: The maximum operating temperature of the system is 130℃, 60℃ higher than plastic pipes.

Long lifetime: 6 times of metal pipes, 2 times of plastic pipes.

Corrosion resistance: Non-corrosive and environmental.

Wall thickness: The wall thickness is 1/4 of plastic pipes, improving 30% flow rate.

Lightweight: 40% unit length of plastic pipes.

Non-scale: The inner wall is smooth and non-scale, and the flow speed rate is 2 times of metal pipes.

Noiseless: Low friction, low material density, no noise in flowing water.

Strong joints: Double-layer glass fiber superposition in joints, hot-melt socket, never leak.

Low cost: Close to the cost of metal pipes and 40% lower than plastic pipes.

Product detail pictures:

Related Product Guide:

We are ready to share our knowledge of marketing worldwide and recommend you suitable products at most aggressive costs. So Profi Tools offer you finest benefit of money and we are ready to produce alongside one another with OEM Factory for Chopped Fiber Composites - Reinforced Thermoplastic Pipe – WANHOO , The product will supply to all over the world, such as: Tajikistan, Hungary, Costa rica, "Make the women more attractive "is our sales philosophy. "Being customers' trusted and preferred brand supplier" is the goal of our company. We've been strict with every part of our work. We sincerely welcome friends to negotiate business and start cooperation. We hope to join hands with friends in different industries to create a brilliant future.

As an international trading company, we have numerous partners, but about your company, I just want to say, you are really good, wide range, good quality, reasonable prices, warm and thoughtful service, advanced technology and equipment and workers have professional training, feedback and product update is timely, in short, this is a very pleasant cooperation, and we look forward to the next cooperation!