Content:

Production Process

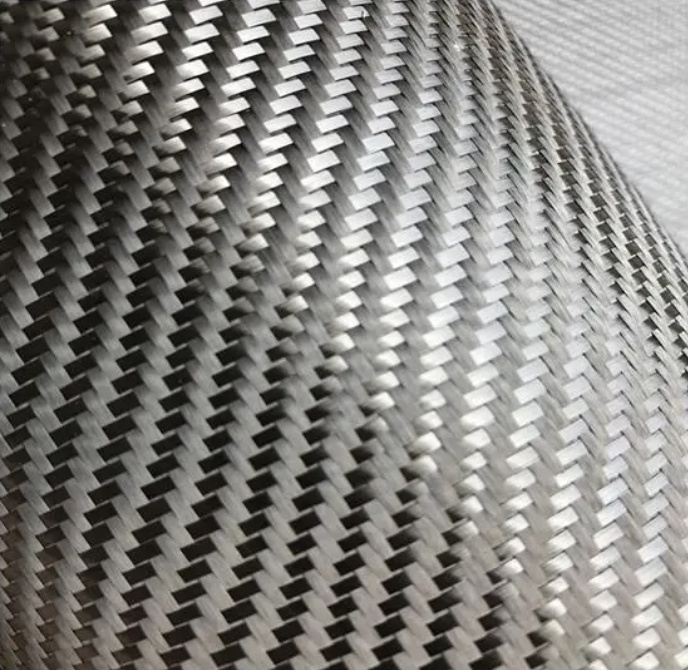

Carbon fiber fabric composites start with carbon fibers derived from organic polymers like polyacrylonitrile (PAN), transformed through heat and chemical treatments into highly crystalline, strong, and lightweight fibers. These fibers are woven into fabrics with different styles—unidirectional, plain weave, or twill weave—each offering unique mechanical properties.

Advantages

These composites excel in strength-to-weight ratios, making them perfect for aerospace, automotive, and sports industries. They’re thermally and electrically conductive, ideal for electronics needing efficient heat dissipation. Additionally, their fatigue resistance is beneficial for dynamic load-bearing structures.

Resin Compatibility

Carbon fiber fabrics pair with resins like epoxy, polyester, and vinyl ester to form composites with specific characteristics. Thermoplastic resins like PEEK and PPS are also used for enhanced toughness.

Applications

Their versatility sees them in aerospace for aircraft and satellite parts, automotive for lightweight body panels, and sports for high-performance equipment. Civil engineering also benefits from their use in structural reinforcement.

Conclusion

Carbon fiber fabric composites are transforming material science with their exceptional properties and adaptability, playing a vital role in the future of engineering and technology.If you need it, you can contact us:email:kaven@newterayfiber.com

Post time: Apr-29-2024